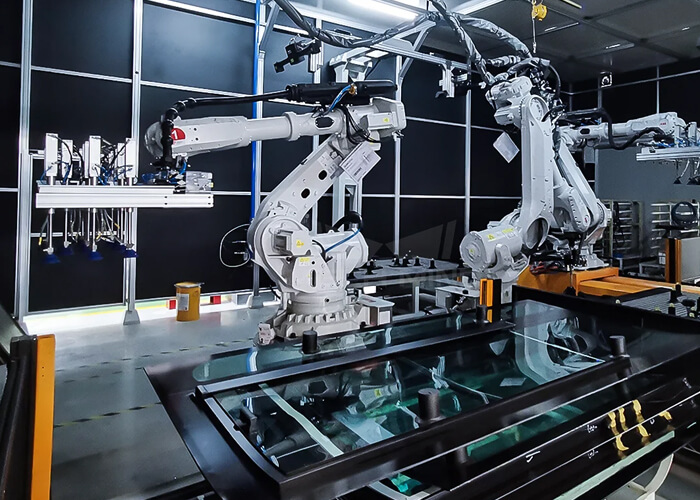

Industrial Automation

Industrial automation involves using control systems, such as computers or robots, to manage equipment in industries like manufacturing, logistics, and energy. This technology increases efficiency, improves safety, and reduces labor costs by automating repetitive tasks.

Key components of industrial automation include:

- Programmable Logic Controllers (PLCs): These are used to control machinery and processes, allowing for precise automation.

- Human-Machine Interfaces (HMIs): These provide a graphical interface for operators to interact with machines and processes.

- Sensors and Actuators: Sensors collect data about the environment or machinery, while actuators perform actions based on that data.

- Industrial Robots: These are programmable machines that can perform a variety of tasks, from welding to assembling.

- Supervisory Control and Data Acquisition (SCADA): This system allows for remote monitoring and control of industrial processes.

- Internet of Things (IoT): Connected devices can communicate data, enabling smarter automation and real-time decision-making.

- Machine Learning and AI: These technologies analyze data to optimize processes and predict maintenance needs.